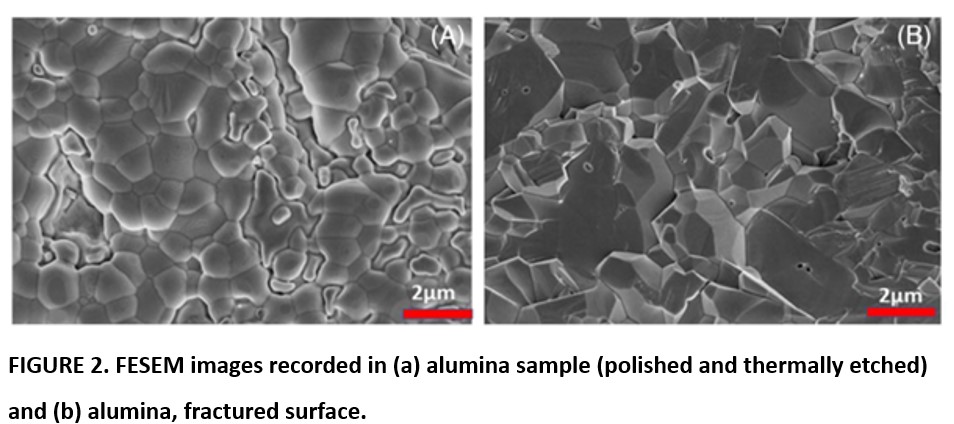

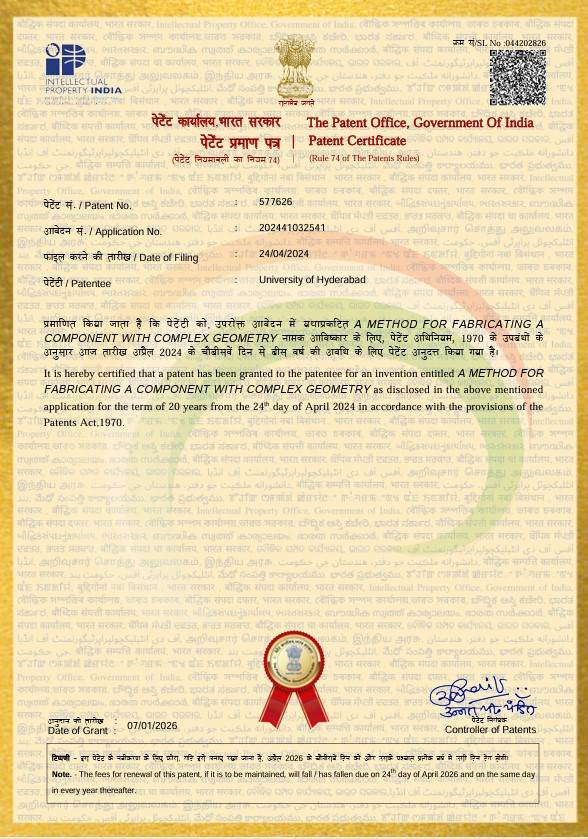

A research team led by Prof. V. Seshu Bai from the School of Physics, University of Hyderabad, has been granted a patent (No. 577626) for their innovative method of fabricating ceramic components of complex shapes. The alumina products thus produced have a uniform density of 99% throughout the volume, fracture toughness of about 3 MPa√m and a flexural strength of about 390 MPa. The process is versatile to be extended to various ceramics like zirconia, tungsten carbide and others. It also allows uniform distribution of requisite second phases as reinforcement, aimed at enhancement of mechanical properties.

Key Features and Applications

Key Features and Applications

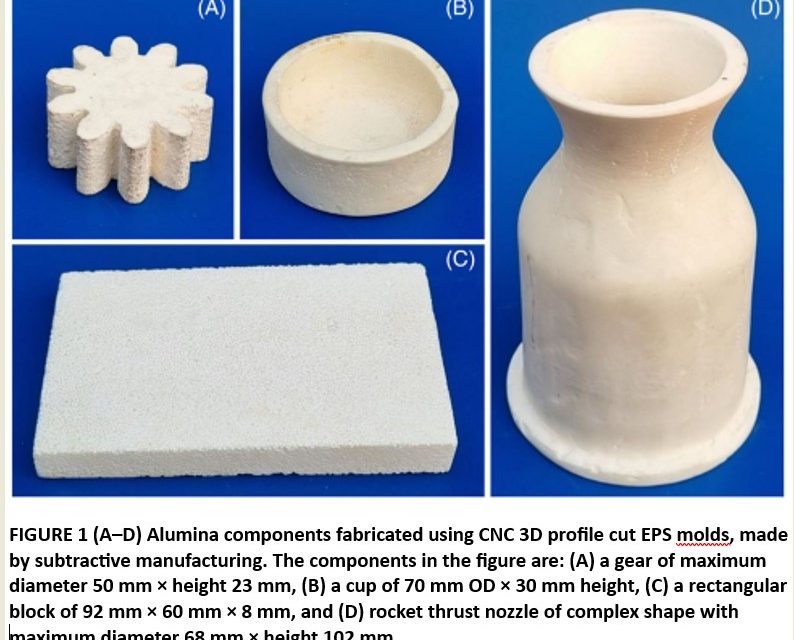

This invention showcases several innovative steps that lead to technical advancement in the fabrication of complex-shaped ceramic parts with excellent mechanical performance. The patented process employs gelcasting of suspended ceramic slurries into expanded polystyrene (EPS) moulds of complex geometry, generated by subtractive manufacturing technique from CAD files. Ceramics are known for their excellent strength and corrosion resistance. This invention gains significance in the light of the fact that ceramic components of various sizes and shapes are widely used in various industrial applications, especially in automobiles, aerospace, and as surgical implants.

Impact and Innovation

This patent projects an inexpensive method of fabricating ceramic parts with uniform properties and good mechanical performance, at low cost and is adaptable by industries. The process not only assures reproducibility and precision, but also enables easy mould removal and avoids mould-green body interaction. This innovative method of fabrication involving setting of concentrated slurries of a precursor sol in precise rapid prototyped moulds enables production of high-performance components. This breakthrough has the potential to benefit various industries and further establish the University of Hyderabad’s research excellence.

Title: A METHOD FOR FABRICATING A COMPONENT WITH COMPLEX GEOMETRY

Patent No. 577626, grant dt. 7th January 2026

Authors: Dr. V. Seshu Bai1, Dr. T. Rajasekharan2, Dr. P. Jeevan Kumar1, Mr. Poly Rose1, Pawan Kumar Verma1 and Dr. A. Rajanikanth1

1 School of Physics, University of Hyderabad, Gachibowli, Hyderabad 500046

2 HYMOD Advanced Products & TIDE-Aspire, University of Hyderabad, Hyderabad 500046